Revolutionizing Fabric Quality with Real-Time AI Detection

threadBridge transforms garment manufacturing with instant defect detection—reducing waste, increasing productivity, and ensuring flawless quality at the speed of production.

Why threadBridge Works

Plug & Play Setup

Installs in minutes, no factory downtime

Easy Operator Training

Simple interface, immediate adoption

Real-Time Detection

Instant feedback, immediate corrections

Hands-Free Operation

Seamless integration with existing workflows

How It Works

Capture

High-res camera scanning fabric with precision

Analyze

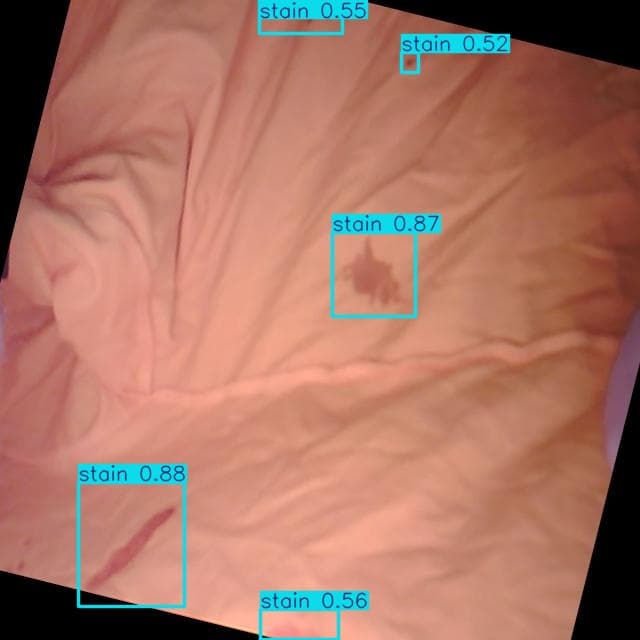

Neural network processes fabric patterns in real-time

Alert

Immediate notifications highlight defects

Edge Devices

Ruggedized mini-computers for on-loom AI

Camera Systems

Industrial lenses tuned for textiles

ML Models

In-house models recognizing complex defects

Live Data Visualization

Real-time defect detection rate

72%

Production efficiency gain

+18%

After threadBridge implementation

Impact & Benefits

Reduce Production Loss

Up to 40% reduction in fabric waste

Instant Quality Assurance

Real-time feedback prevents defective batches

Save Time & Labor

Automated detection replaces manual inspection

Scalable Integration

Grows with your production capacity

Ready to revolutionize your factory's QC process?

Join our pilot program and be among the first to harness real-time defect detection. Let's collaborate to reduce rework, safeguard profit margins, and raise the bar for garment quality—together.

Live Demo: Defect Detection Simulator

Select a fabric image to detect defects

threadBridge vs Traditional QC

| Capability | threadBridge | Traditional QC |

|---|---|---|

| Detection Speed | Real-time (ms) | Minutes to hours |

| Consistency | 99%+ consistent | Varies by operator |

| Training | Minutes | Weeks |

| Integration | Plug & play | Custom retrofit |

About threadBridge

We're textile technology pioneers, combining deep industry knowledge with cutting-edge AI to solve manufacturing's most persistent quality challenges.

2023

Founded with a mission to redefine textile QC

2024

Proprietary ML models trained on diverse defects

2025

Pilot program with leading garment manufacturers